Topring Aluminum Pipe Systems

Why Aluminum is the definitive solution for Compressed Air Systems

Choosing the right material for your compressed air system involves more than just initial costs. Upfront expenses are minor compared to the overall impact. Energy consumption accounts for about 76% of total costs. Opt for materials that enhance energy efficiency and system optimization for a more sustainable solution.

Choosing the right material is crucial as it affects efficiency, leak tightness, durability, adaptability, maintenance, installation, and long-term overall costs. Understanding these factors ensures informed decisions and optimal system performance.

100% aluminium compressed air systems maintain higher and more stable pressure compared to systems with aluminum pipes and plastic fittings.

The Efficiencies of Aluminum Compressed Air Networks

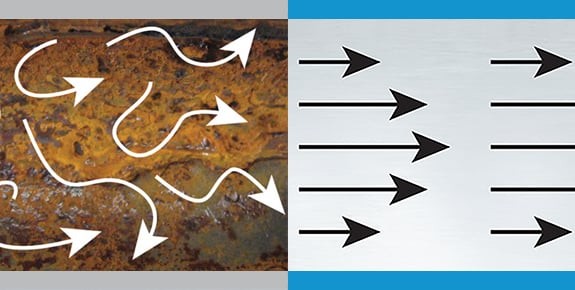

Corrosion Resistant

Aluminum compressed air pipes are all corrosion resistance due to their natural oxide layer and chemical resistance. This ensures that the pipes maintain their internal diameter over time, preserving performance, ensuring long-lasting efficiency, low maintenance, and improved air quality.

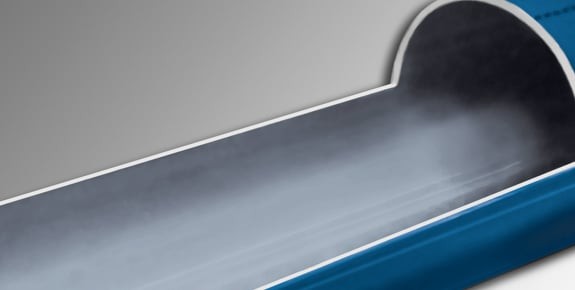

Minimal Pressure Loss

The smooth interior surface of aluminum pipes reduces friction, maintaining efficient air flow. This minimizes energy consumption and ensure consistent pressure levels, enhancing overall system performance and reducing operations costs.

A Zero Leak System

Aluminum pipes and fittings are designed for leak tightness, addressing air leaks through precision engineering and high-quality fittings. This ensures secure seals and maintains system efficiency.

CRN Fittings

Topring aluminum fittings are designed to offer the most effective leak-tight solution of all other systems available for compressed air distribution. The wide variety of connection options provide infinite installation possibilities.

Connection Options for Every Situation

Compression Fittings: Designed with a double-lobe gasket ensuring the hermeticity of the system. An assembly gel free to oil or any type of contaminant facilities the insertion of the pipe into the fitting

Flange Connection : Featuring an ANSI/ASME general-purpose flange ensuring seamless integration. Specifically designed for connecting your system to a compressor, dryer, or existing setup.

V-Clamp Connection: Directly connect two fittings together using a clamp, eliminating the need to cut pipes or install flanges. This design allows for easy installation and eliminates assembly errors.

Technical Specifications

- Maximum working pressure: 232 PSI

- Fluids: Compressed air, vacuum, inert gases, nitrogen

- Vacuum level: -29.94 in Hg//0.98 BAR

- Burst pressure: 1160 PSI with coefficient of 5:1

- Environment: Material 100% recyclable, silicone-free, oil free

- Fluid temperature: -20 to 80 C

- Resistant to: Corrosion, harsh environment, mechanical shocks, thermal variations, mineral and synthetic compressor oils, ultraviolet (UV)

Pipes

- Material: EN AW 6063 extruded aluminum alloy

- Coating: Electrostatic paint (Complaint with RoHS standard)

- Colour: Ble RAL 5012 (ISO Colour)

- Diameters of 3 m (9.8 ft) pipes: 16, 20 and 25 mm

- Diameter of 4 m (13 ft) pipes: 32 mm

- Diameter of 5.5 m (18 ft) pipes: 20, 25, 32, 40. 50, 63, 80, 100 and 160 mm

- Manufacturing process: Calibrated extrusion, Non-welded

Fittings

- Materials: 100% aluminum body and nut, EN AB 46100, stainless steel gripping teeth, NBR seal with PTFE coated treatment

- Diameter of compressor fittings: 16, 20, 25, 32, 40, 50, 63, 80, 100 and 160 mm

- Diameter of compact connection fittings: 50, 63, 80, 100 and 160 mm

Calgary

Lethbridge

Phone: 403-308-6718